Damascus steel has a long and illustrious history as a steel of top choice for knives and swords. Damascus steel blades are stunning in their beauty and their efficacy. Nowadays, they are primarily used in the kitchen for precise, powerful cutting.

However, about 1500 years ago, most Damascus steel blades were used in weapons. Some bladesmiths still make swords and knives by using the modern Damascus technique, either professionally or in their home forges.

The original method for forging Damascus steel blades was lost about three hundred years ago after prevailing for a millennium and a half. Bladesmiths had to rely on ancient writings and obscure techniques of forging to come up with the modern Damascus blade.

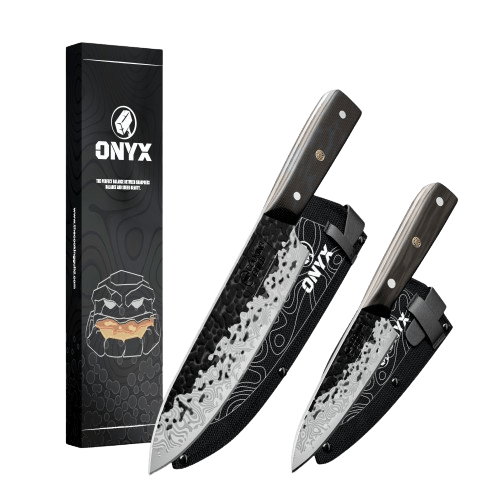

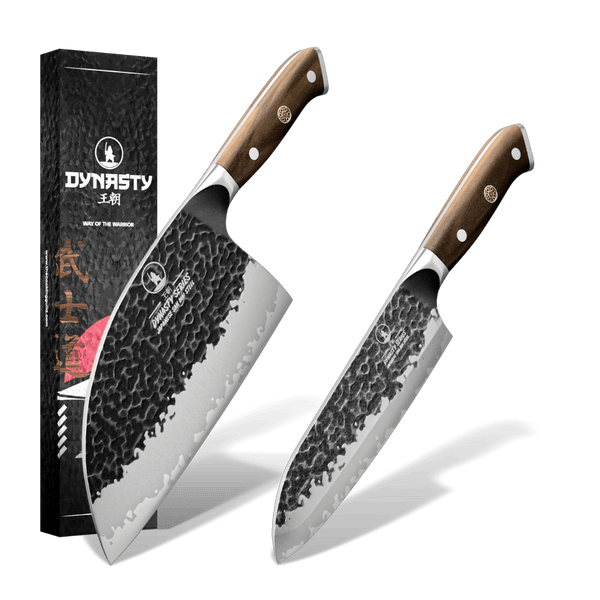

Damascus steel blades, whether knives, daggers, or swords, are easily recognizable. They appear to have a wavy, watery pattern along the blade, and they are easily one of the most beautiful types of knives for this reason.

The True Origin of Damascus Steel

It is accepted by most scholars that the Syrians of Damascus perfected the method, hence the name. The Damascus steel blades forged in Syria from the fourth century to the early eighteenth century were the most sought-after blades for swords because of the quality of the forge.

The raw material for the blades came from a type of iron ore called wootz that originated in India. The Syrians would obtain the wootz and repeatedly layer it over itself. Damascus steel is made using folded layers to create up to 300 layers of forged steel and even more. Some bladesmiths hit one million layers. This process takes practice, patience, and time, but the results are worth it. The wootz ore method was lost, and now there are modern ways of forging Damascus steel blades, which we will discuss below.

Why would anyone choose to forge a knife or sword this way, even if now we only have the modern method, not the lost Damascus forging method? Damascus steel blades are not only highly sought after for their impeccable craftsmanship—their durability and flexibility are second to no other style of forging, save perhaps katanas from Japan. The layers of the steel heated, hammered out, layered, and cooled over and over again produce a blade that holds its edge for longer than most, and a durable blade that is strong yet flexible.

The detailed manufacturing process makes Damascus steel blades not only stunningly beautiful, but also practical pieces which can last a lifetime, whether you’re using them to julienne vegetables, scale fish, or survive in the bush.

How does one forge Damascus steel blades?

Damascus steel is created by repeatedly layering the raw materials for the blade. This process involves heating and cooling many more times than traditional forging. This repetitive heating-and-cooling process is as much a labor of love as it is an impressive technique that shows the patience of the forger and the quality of the end product.

One bladesmith named Alex Steele started with 31 layers to forge his Damascus steel blade. He heated and folded these layers over and over again until he ended up with a million-layered steel block from which he made a karambit (a curved blade used in defense).

Recognizing True Modern Damascus Blades

As of yet, nobody has been able to reverse engineer the process of making Damascus steel to discover the original method of ancient and medieval times. As a result, modern Damascus steel is made in one of two ways: San-Mai and the typical technique that uses more than three layers.

San-Mai Damascus blades use three layers, the inner layer being made from carbon steel and the outer two layers usually made of stainless steel. This method doesn’t take nearly as long as the most common Damascus layering technique because there is no folding required. Nonetheless, it still requires several materials to forge together to make a strong, practical blade.

When performing the other method of Damascus steel forging, two to five different alloys are folded together, depending on the bladesmith’s preference and experience. These metals are repeatedly folded together to create one block from which they will then forge the blade. This intricately layered folding technique creates the beautiful Damascus steel designs on the blade we know and love.

Watch out for imitations. There are cheap forgeries of Damascus steel blades which are simply laser etched or engraved with patterns resembling those of true Damascus blades. They are cheaper, but they are dupes, and they do not possess the strength or durability of Damascus steel. The etching will also eventually wear off.

Whether you choose a blade for protection, bushcraft, or preparing amazing culinary delights, Damascus steel is excellent for its sharpness, durability, and resilience. You can even take our knife quiz to see which knife is the best fit for your needs.